£0.00

0A guide to buying castors – next steps

This is a quick reference guide to help you to select the correct castor to meet your requirements. For a more general guide with information about wheels and castors please read our guide to buying wheels and castors.

When buying castors there’s a huge range to choose from including: heavy duty, zinc plated, stainless steel, pneumatic, jacking, gate, twin wheels amongst many further options.

To be honest there are so many choices that it can be overwhelming. The castor that you ideally need will depend on many factors and you must think carefully about what you intend to use the castors for;

- What equipment you will be moving with them?

- How often they will be used?

- How far you will be moving your equipment and over what surfaces?

- How much space do you have for movement?

You will also need to consider other things such as;

- Do you need swivel or fixed castors – Or braked castors?

- How will you attach your castors?

- What sort of weight will you be moving?

- Where will they be used?

- What environment will the castors be used in?

- What surface will the castors be used on?

- Will they be used in high or low temperatures?

- Will they be used where there are chemicals?

- Do you need to consider anti-static castors?

- Are these castors being towed and at what speed?

Type of castor

Start by considering the benefits and features of each type of castor by looking at the table below.

| Type of castor | Recommended Uses (Not an exhaustive list) | Features |

|---|---|---|

| Light duty pressed steel | – For light duty and institutional use – Display equipment – Hospitality equipment – Mailrooms – Pharmaceuticals Educational establishments | – Swivel, swivel with brake and fixed options. – Available for top plate or single bolt hole fixing, with 5 different castor wheel options. – Wheel diameters from 35mm to 150mm – Load ranges from 25kg up to 200kg per caster |

| Medium Duty Pressed Steel castors and Heavy Duty Pressed Steel Castors | – Picking trolleys – Warehouse trolleys – Dollies – Manual handling equipment | – For loads from 50kg up to 1000kg per castor. – Swivel, fixed or swivel with lockable brakes – 10 different wheel options – Wheel diameters from 50mm to 200mm – Top plate or single bolt hole fixing |

| Medium / heavy Stainless Steel | – Medical – Pharmaceuticals – Food / catering – Wet environments | – For loads 50kg up to 500kg per castor. – Swivel, fixed or swivel with lockable brakes – 10 different wheel options – Wheel diameters from 50mm to 200mm – Top plate or single bolt hole fixing |

| High temperature pressed steel and fabricated | – Bakeries – Power coating – Autoclaves – Paint ovens | – Top plate or single bolt hole fixing – 9 different wheel options – Wheel diameters from 80mm to 200mm – Temperature ranges from -40° up to +400° – Load ranges 150kg to 700kg per castor |

| Medium/Heavy duty fabricated | – Manual and towing applications – Stillages – Lineside trolleys – Tipping skips – Cradles and bogies – Tooling and jigs | – Stronger than pressed steel. – Fixed, swivel, swivel with brake wheel options – Top plate only fixing – Loads from 180kg to 11,500kg per castor – Wheel diameters 70mm to 400mm |

| Pneumatic and puncture proof pressed steel & fabricated castors | – Use on softer or rougher terrains – Sports equipment – Flat bed trolleys & trucks – Fruit picking trolleys – Garden centres – Outdoor equipment | – Multiple castor options – but top plate fixing only – Choice of castor heights & treads – Fixed or swivel, with/without brakes – Wheel diameters from 200mm to 260mm. – Load capacity from 70kg to 270kg per castor. |

| Low, Medium and Heavy Duty Jacking Castors | – Staging – Adjustable trolleys – Gantries – Tooling | – Jacking Castors safely raise and move heavy objects in any direction – Bar or crank handle operation with either swivel or swivel & brake castors – 5 different wheel options are available – Wheel diameters from 75mm to 300mm – Load ranges from 140kg up to 2800kg per castor |

| Gate Castors | – Gardens – Paddocks – Driveways – Farms – Business Premises – Commercial & Industrial Sites | – Easy opening/closing of gates – Load capacity to 75kg per castor – Spring loaded to absorb shocks from uneven ground – Fixed or swivel wheels 100mm diameter( Use fixed for a wide, single gate, use swivel on shorter widths/distances) – Orientation of the fixed castor easily adjusted. |

| Scenery skates and the Ezeelift systems | – Opera / ballet – Theatres – Concert Venues – Television Studios – Museums – Film Locations | – Safely & easily move heavy scenery, props etc. – Top plate or stem fixing with 4 different wheel options – Wheel diameters 35mm to 125mm. – Load capacity from 50kg to 1000kg per castor. |

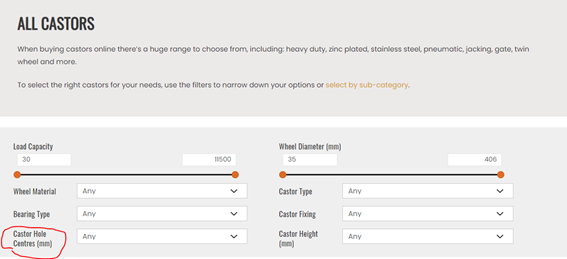

Once you have a better idea of the type of castor you need you can then refine that choice by visiting our castors by category product page. Here you can use our handy filters to help you narrow down your choices and ensure that you select the right wheel or castor for your application:

If at any stage you would like to talk to an experienced sales support person please just call us on 01249 822222. We would be happy to help you.

Load Capacity

As each castor is designed to support a maximum load weight, it is vital to stay within this maximum limit for safety reasons and to avoid damage to the castor or your equipment.

Be aware that the condition of the surface on which you will be using your castors and wheels must also be considered. A badly cracked surface or one with numerous uneven joints or gullies will likely add extra loading onto individual castors. On an uneven surface some of the castors may lose contact with the floor meaning extra weight will fall on the other castors at that time. If this is the case in your scenario you must factor that sudden extra loading into your calculations.

You can see an overview of the maximum load for each type of castor on our castors overview page https://www.bilgroup.co.uk/product-category/castors/ before you select the type of castor. You can then use the handy sliding filter option to further narrow down your results.

If you need any help in understanding or calculating your castor load limits please contact us – we are ready to help you.

Wheel Material

Having selected a castor type and checked that the load rating is suitable for your application, you will be able to use the wheel material filter to further guide you towards the ideal castor. Many of our castors come in a range of wheel material options. See the table below for details about the suitability of different wheel types for your application.

| Wheel type | Features | Recommended uses |

|---|---|---|

| Polypropylene Wheels and Nylon Wheels | – Hard tread – Low rolling resistance – Lightweight – Low wear – Low cost | – Hard or soft flooring |

| Standard rubber wheels | – Soft tread – Lightweight – Non marking – grey tyres – Low noise – Good grip and control | – Ideal for hard surfaces – Warehouses |

| Elastic rubber wheels | – Extra soft tread – High elasticity – Non marking – Low noise – Good grip and control – smooth ride – high load capacity | – Ideal for hard surfaces – Warehouses |

| Polyurethane wheels | – Good Appearance – Good Grip & Control – Low Noise, – Heavy Duty & Long Life – Ideal for hard surfaces | – Picking trolleys – Warehouse trolleys – Dollies – Manual handling equipment |

| High temperature wheels | – Operate up to 4000C | – Bakeries – Powder coating – Autoclaves – Paint ovens |

| Cast iron and Steel wheels | – Heavy and extra heavy duty | – High temperature environments – Foundries – Rail and track wheels – Bakeries – Powder coating |

| Anti-static and Electrically conductive wheels | – Wheel diameter up to 200mm – Conductivity resistance R≤ 50 Mega Ohm – load ranges up to 500kg per wheel | – Medical spaces – Pharmaceutical spaces – Health and safety equipment – Clean rooms – Labs |

| Pneumatic Wheels and Puncture proof wheels | – Wheel diameter from 200 mm up to 400 mm – Plain, roller and ball bearing options – Load ranges from 75kg up to 350kg per wheel | – Sports equipment – Flatbed trucks & trolleys – Fruit picking trolleys – Garden centres – Outdoor equipment |

Wheel diameter

Our different wheel types come in a range of diameters and you can use the slider to help narrow the wheel selection down to the size of diameter you require. Generally, wheels with larger diameters are suitable for heavier loads and are easier to move.

The diameter of the wheel is found by measuring between the outside edges of the wheel.

Bearing Type

The type of bearing that you choose depends on;

- the type of wheel,

- the load rating

- your application.

Choose between plain bearings, roller bearings or ball bearings. Generally, ball bearings are used at higher speeds whereas roller bearings perform better under shock and heavier loads. We would be happy to discuss your requirements and advise on which bearings type would be most suitable for you.

The Castor Hole

The castor hole size is simply found by measuring the diameter of the hole in the centre of the castor – also known as the ‘bore’. The bore (hole) size can be adjusted using collars / tubes if necessary.

You can use the drop-down filters to select the size of the castor hole (mm) that you need. (Click the image below to go to this page).

Castor Type

Choose between fixed castors, swivel castors or swivel with brake castors.

- Swivel castors allow movement in any direction and so make it easier to manoeuvre equipment and goods around corners and in areas where there is not much space.

- Fixed castors allow movement laterally – backwards and forwards only.

- Braked castors – brakes can be fitted to swivel castors which can stop movement and the swivel.

In some cases, it’s beneficial to use a mixture of castor configurations to get the ideal solution for your application and environment as detailed below:

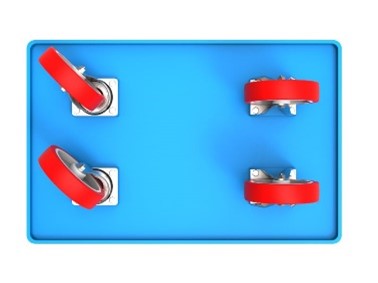

Two swivel + two fixed – this offers the safest handling and load control with good steering on straight runs and cambers. When moving, the two fixed castors should lead with the swivel castors at the back for easier manoeuvrability. This configuration works for most loads. Each castor load capacity should be calculated to be at least 33% of total load as when moving one or other of the castors may lose contact on uneven floors thereby putting its load onto the remaining castors.

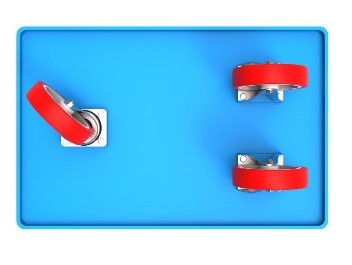

One swivel & two fixed – this option allows easy manoeuvrability but is only recommended for light loads. For this configuration, calculate the castor load capacity to b e a minimum of 40% of the total load weight.

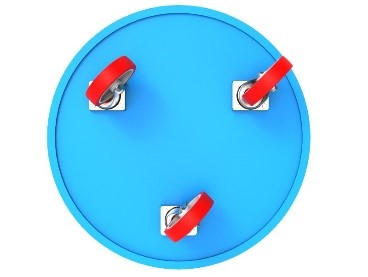

Three swivel – this allows maximum manoeuvrability, but it will be difficult to control on straight runs, sloping or uneven surfaces and so is advised only for small trolleys with light loads. For this configuration calculate castor load capacity to be a minimum of 40% of the total load weight.

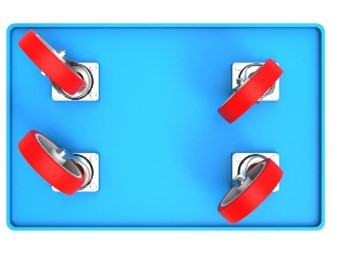

Four swivel –gives maximum manoeuvrability and is ideal for smaller spaces but harder to control on longer straight runs, or sloping and uneven surfaces. This can be addressed by using castors with directional locks. Each castor load capacity should be calculated to be at least 33% of total load as, when moving one or other castors may lose contact on uneven floors putting its load onto the remaining castors

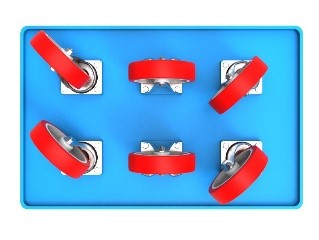

Four swivel & two fixed, centrally pivoting – usually used on long trolleys to optimise control and manoeuvrability. The two central fixed castors are usually one size larger or the same size as the swivel castors and fitted with 25mm packing under the top plate. Castor capacity for the fixed castors should be at least 50% of total gross load.

Two swivel & two fixed, centrally pivoting – similar to the above but less stable if the load is not evenly distributed. The two central fixed castors are usually the same size as the swivel or one size larger and fitted with a 25mm packing under the top plate. Castor capacity for the fixed castors should be at least 50% of total gross load.

Castor Fixing

You can choose between either a single bolt hole mounting or a plate mounting for your castors.Castors using a single bolt hole mounting are limited to loads of up to 500kg having a fastener through the centre of the swivel head. These are available in a choice of Swivel, Swivel Braked* & Fixed (*Braked castors are only available in our BZRA & BZM ranges.)

If choosing a plate mounting, you will need to measure its length and width, the number of holes and the spacing between these.

Plate mountings, tend to be more robust and are usually the ideal choice if there is room for them to be attached. There are a range of sizes available to give more stability, take greater loads and these can be either fixed, swivel or braked. With swivel options you can either consider the use of a directional lock.

Castor Height

All of our castors come in a variety of heights. Simply choose the height that is most suitable for your application and use our product search filter to show available castors matching that height range see Castor Height Search.

Of course, we appreciate that every application is going to be unique in some way. This is why we have our highly experienced team on hand to run through your process and application and to support you in selecting the most suitable castors for you. Please don’t hesitate in contacting a member of the team on 01249 822222 or email us at sales@bilgroup.co.uk.