£0.00

0A Guide to High Temperature wheels

This guide will give you an overview of our high temperature wheels and castors and support you in choosing a solution suitable to your requirements.

High temperature, heat-resistant wheels are essential for use in temperatures ranging from -40 degrees up to 400 degrees. This makes them ideal for any high temperature applications involving ovens such as kilns, bakeries, food processing factories, autoclaves, powder coating and also for low temperature applications involving freezers like freeze drying processes.

In addition to withstanding extremely high (and low) temperatures, heat resistant wheels and castors should also have other important features; they need to be easy to clean for hygiene purposes, non-marking to avoid damage to floor surfaces, anti-corrosive to withstand chemicals and oils that may be present in the processes and easy to move whilst supporting heavy loads.

Our high temperature wheel range is extensive, offering you a variety of options to meet your needs with the suitable wheel being dependent on several variables including the application itself, the weight or load of your product and the temperature range you are require the wheel to work in.

For more detail about the many options available including;

- load capacity

- wheel bore (mm)

- wheel hub (mm)

- wheel diameter (mm)

- wheel material

- bearing type

View the High Temperature Wheels section.

You can quickly identify just which wheels are ideal for your business using a range of fast finder filters. If you would like an expert to help you to select the ideal high temperature wheel for your application just contact our highly experienced team on 01249 822222 or email sales@bilgroup.co.uk. We would be delighted to hear from you.

Ditherm® High Temperature Wheels

Our range of Ditherm® wheels are manufactured with special fibres and moulded under pressure into a high-quality durable and versatile wheel. These wheels feature a harder surface, providing low roll resistance so making them suitable for use on softer floorings. The material is manufactured to be non-marking therefore reducing the risk of floor damage.

Our Ditherm® wheels come in both black and red colouring, with the red wheel able to withstand temperatures up to 400°C.

Black Ditherm® (-40°C to +300°C)

Red Ditherm® (-40°C to +400°C)

High temperature Ditherm® wheels have an excellent resistance to many different compounds regularly faced including; water, most solvents, oils, acids, and chemicals.

These Ditherm wheels are fully certified for use in the food industry and have excellent fire-smoke-toxicity properties to ensure extra safety. They are designed and tested specifically with high resistance to thermal shock which is caused by a quick increase or reduction in temperature, often peaking to 400°C and dropping down as low as -40°C.

Overall Ditherm® wheels are an excellent and effective solution for high temperature applications able to cope with hugely varying temperatures and with excellent chemical resistance, they also provide peace of mind that they will provide a long service life.

Thermoplastic Heat Resistant Wheels

Thermoplastic high temperature wheels are manufactured with an exclusive composite material (used only for this range) designed and developed over many years which is specifically designed for longevity and durability.

Our thermoplastic wheels come with varying load capacities of up to 1000kg per wheel and also have a non-marking foundation material in order to protect your flooring.

The thermoplastic range can operate in temperatures of -40°C up to higher temperatures of +280°C.

Thermoplastic wheels feature excellent resistance to a range of compounds including water, humidity and steam, solvents, oils, acids and chemicals. These wheels also feature great fire-smoke toxicity properties and are certified for use in the food industry. As they can cope with temperatures of -40°C, thermoplastic wheels also work well in freezers, chillers and blast freezing applications. They have also been tested to resist sudden jumps of temperature of up to 280°C within 60 seconds.

Overall thermoplastic wheels give you the confidence that they will provide a durable and fitting solution for varied temperatures, working effectively in extreme heat and cold environments.

Nylon 6 (Polyamide)

High temperature Nylon 6 wheels are manufactured in high grade polyamide and filled with glass fibres. After adding additional natural fibres, they are then moulded into shape through a vacuum and material drying process making them strong and durable.

Nylon6 features high resistance to water humidity and steam along with oils and solvents. They feature good fire smoke toxicity properties and are certified for use in the food industry. Nylon6 is typically used for lower heat temperatures of up to 130°C but is durable in many applications. With capacity to work at -30°C these wheels will also work well in freezers and chillers and provide resistance against thermal shock. They have been tested to resist sudden jumps of temperature up to 150°C within 60 seconds.

An added feature of the Nylon6 is its good resistance against heavy impacts therefore increasing the service life of the wheel.

Overall Nylon6 wheels are a good all-round option for lower temperature applications but where durability is key.

Epoxy Resin High Temperature Wheels

Our Epoxy resin wheels are regarded as our most hard wearing wheel across all of the ranges. We developed this wheel type with a major food manufacturer in the UK and despite its higher initial cost, Epoxy resin has become one of the bestselling, most popular wheels we supply across all of our castor and wheel ranges.

Epoxy resin wheels are manufactured in a very similar way to phenolic wheels and are made from shock and impact resistant epoxy resin materials. They feature excellent resistance to most chemicals, water and steam. Fitted with sealed precision ball bearings and a anti rust coating the epoxy resin wheel has excellent adhesion and is highly durable

Their suitability in temperature ranges from -20°C up to 250°C, make them a good all-round wheel for numerous applications within a bakery or food manufacturing environment.

With this wheel, the durability is widely proven and these high temperature wheels have the capacity to outlast many other wheel types multiple times over reducing down time and maintenance requirements. Therefore, it is important not be detracted by the unit price and remember that ‘you get what you pay for’.

In short summary our Epoxy Resin wheels can be described as the go to for regular applications if looking to improve durability and service life compared to standard high temperature wheels that are available on the market.

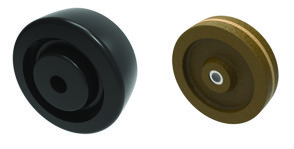

Phenolic Heat Resistant Wheels

Phenolic wheels are typically used in baking ovens and autoclaves. Our range provides two options: a black phenolic wheel capable of withstanding temperatures of up to 120°C and a brown phenolic wheel with a higher temperature range up to 250°C. Phenolic wheels have a design and hardness comparable with a bowling ball, making them easy to manoeuvre over varied floor surfaces.

Phenolic wheels are made by taking a phenolic resin and moulding it into the wheel shape to the required size under high pressure and temperature. These high temperature wheels being relatively inexpensive represent excellent value for money and our range is capable of withstanding higher load capacities, making them ideal for heavier duty racking.

Phenolic wheels feature chemical resisting properties preventing adherence to oil, grease and liquids.

Overall phenolic wheels are ideal for irregular usage due to their low cost but versatile properties.

Glass filled Technopolymer High Temperature Wheels

Glass filled Technoploymer is a mouldable composite material featuring a mix of glass fibres with a polymer compound. The compound itself is used to manufacture structural components through injection or compression moulding.

These high temperature wheels feature a distinct hardness to the material, improving the rigidity and strength for longer service performance.

This range is offered in 80mm & 100mm wheel options which are the most popular sizing for most commercial oven racks.

Temperature ranges for this wheel type range from -40°C up to 280°C making them suitable for a range of applications across the food manufacturing and bakery industries.

We hope you found this short guide useful.

At BIL we are confident that we will have the best wheels available to meet your requirements.

We know from our 50 years of selling castors and wheels that every application is different and this is why we have our experienced sales support team ready to work through your processes and applications. We want to assist you in selecting the most suitable, best value high temperature wheels for your business.

Please don’t hesitate to contact a member of the team on 01249 822222 or email us at sales@bilgroup.co.uk for further information. We are here to help.